SERVICES

In addition to the standardized production of panels, we can carry out a range of related work aimed at offering a complete package of ancillary processing on products and customer support for the design and engineering of special solutions. Non-certified climatic and mechanical tests can also be carried out on site on behalf of the customer, thanks to an internal laboratory.

SUPPLEMENTARY WORK IN OUR FACILITIES

Starcell has an internal fleet of processing machines for finishing, cutting to size, squaring, drilling, shaping and milling the panels, whatever the type of skin without finish that the panels are based on: galvanized steel, stainless steel, wood, aluminium, etc.

Our materials warehouse stores a broad assortment of decorative skins to ensure fast delivery. All our supplementary work is managed by computerized processes that ensure reliable workflows and timely deliveries. A solid and efficient logistics network completes the range of our services.

ADDITIONAL OUTSOURCED MACHINING

Starcell has a network of trusted partners who usually outsource special work to order, particularly with regard to cutting and gluing stone or glass-based materials and cutting to size and edgebanding panels with wood-based skins and finishes using HPL laminates and solid surfaces.

Our production chain can manage complex orders (quantity and variety of materials, thicknesses and sizes) and varied series (different processes on each panel), thanks to an efficient, flexible and dynamic work organization.

CLIMATE AND MECHANICAL TESTS

Starcell’s ability to support its customers at every stage (from design to after-sales) has boosted the growth of its research and development department which, on the one hand, is responsible for product innovation with a view to possible future applications, and on the other hand responds to direct customer requests for the design of customised solutions and their testing by means of accurate physical-mechanical tests.

Mechanical compression, tensile, bending and tearing tests can be carried out on behalf of our customers. In addition, a climate chamber is available that can simultaneously contain up to five panels, with a surface area of more than 2 square meters. Thanks to this, we can simulate the behaviour of materials with variations in temperature and humidity for the entire life of the sandwich panel.

SPECIAL WORKINGS

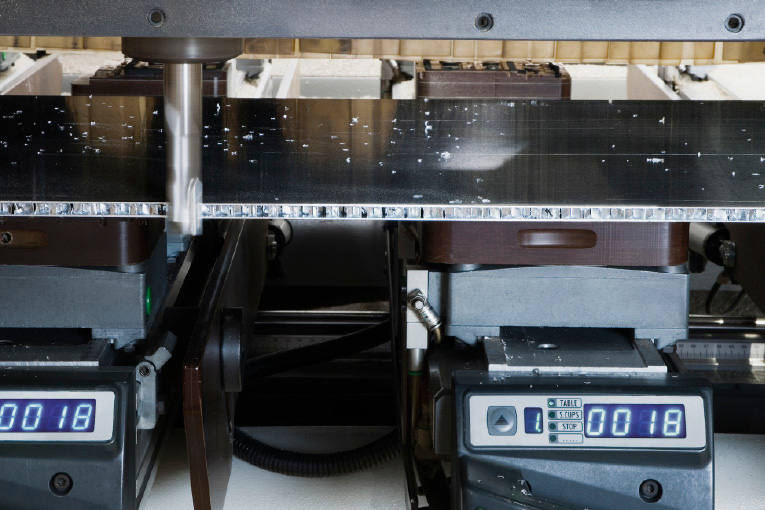

EDGE PROCESSING

All panels can be finished by applying various types of edging:

A) IN-LINE EDGEBANDING: gluing an ABS, PVC or aluminium edge using an in-line machine. The edge may be colour-coordinated with the panel. This type of edging guarantees excellent resistance to tearing and is suitable for mass production thanks to its low cost.

B) GLUED EDGE: a variant of in-line edgebanding in which the core is first filled with expanding foam and then an edge band is glued on it. Suitable solution for thick panels; medium cost.

C) OPEN PROFILE EDGEBANDING: insertion of an edge profile in the panel’s edge. Recommended solution for small series production, given the complexity of the work.

D) FOLDING: processing that consists of folding the ends of the skin by 90° to give the panel the appearance of a solid piece. Given the difficulty of this method, folding is not compatible with industrial production.

FASTENING SYSTEMS

The panels can be completed with a wide range of accessories and mechanical fasteners to be used for quick and safe installation.

The back surface of the panels can be machined to add rivets or threaded inserts useful for fixing brackets and hooks.

For several years Starcell has been active in the ventilated and continuous façade sector and has supplied sandwich panels (aluminium honeycomb) to support stone or other types of cladding.

The experience gained in this field has led to a close collaboration with both specialist companies and established professionals in this sector that allows us to offer, together with honeycomb panels, both fixing solutions and support for laying. Starcell can therefore supply the entire system (including assembly, carried out jointly with partner companies) or simply the panels, leaving it up to the customer to decide upon the type of installation.