Internal

cladding

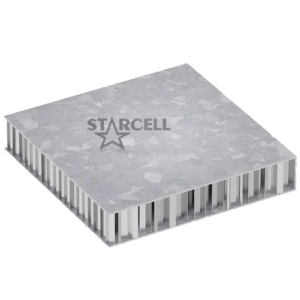

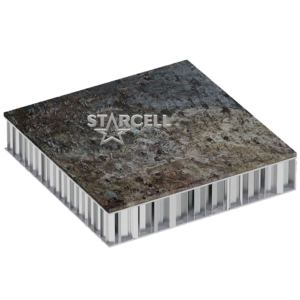

Our aluminium honeycomb panels are ideal for covering the inside walls of railway carriages

Doors, floors

and furniture

Aluminium honeycomb brilliantly solves the problems of weight, mechanical resistance and compliance with safety standards typical of the rail transport sector

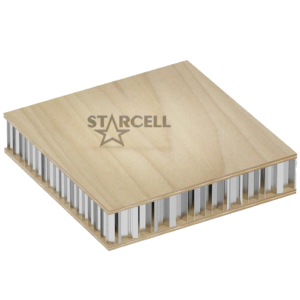

Ceilings

Our sandwich panels meet all regulatory requirements and make it possible to create comfortable and bright environments inside the carriages

RAIL

The construction of safe, fast and cheap trains is one of mankind’s great challenges: it is here that the most complex problems concerning materials are concentrated, and technological progress continues to advance to overcome of the limits previously reached. Starcell is actively involved in this process since it has always been dedicated to scientific research on composite materials. These materials are of great interest for the rail transport sector because their use significantly reduces the overall weight of the train, providing clear advantages in terms of energy consumption, efficiency and resource savings.

Railway carriages

Starcell’s success in the rail sector, particularly on high-speed train coaches, is also due to the use of innovative, low-weight and high-performance materials such as sandwich panels. These materials have enabled designers to improve travel comfort while complying with regulations on toxic fumes and fire resistance. With the breadth of its product range and its modern production and processing lines, Starcell is an ideal partner for designers and manufacturers, who can produce the components of their coaches at a single production site.

Starcell uses three different production processes that allow the use of multiple types of coating and finishing materials.