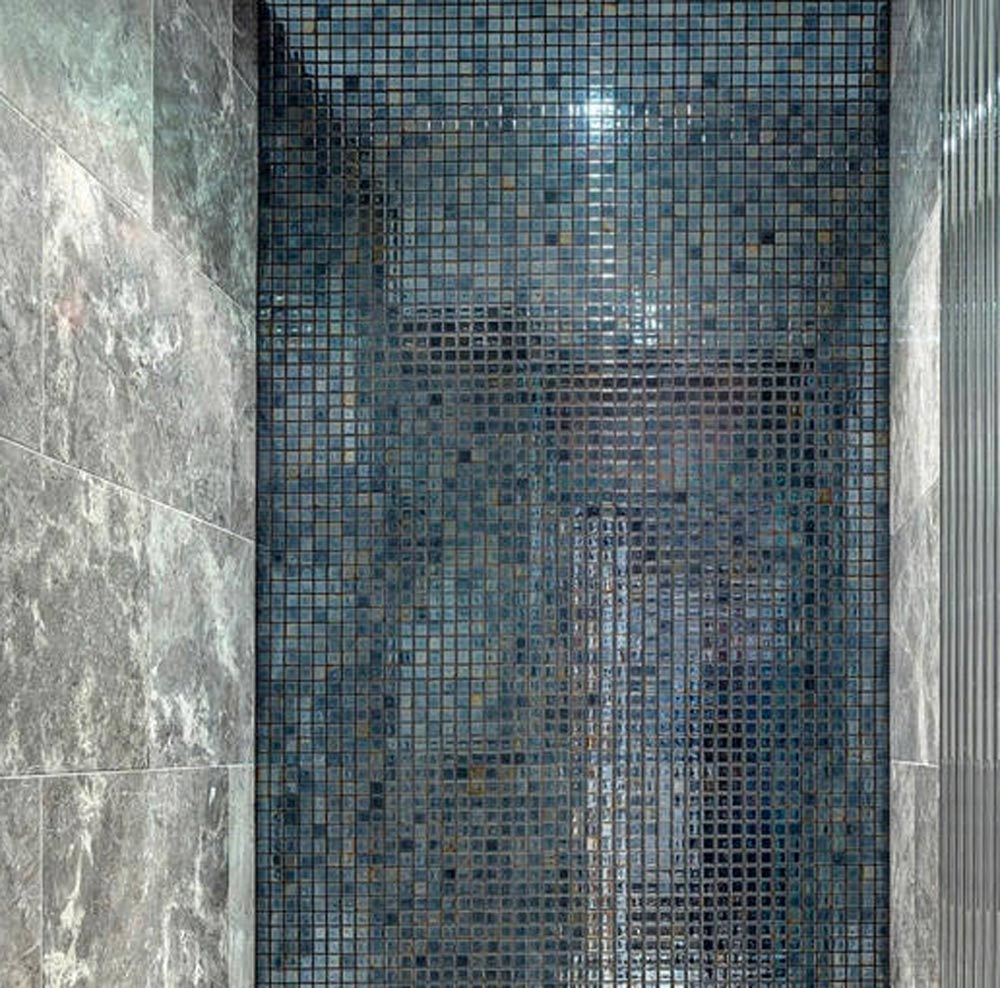

Wellness

centres

The sandwich panels that we produce for the mosaic and lightened marble sector make it possible to prefabricate large modules to be joined in place very rapidly

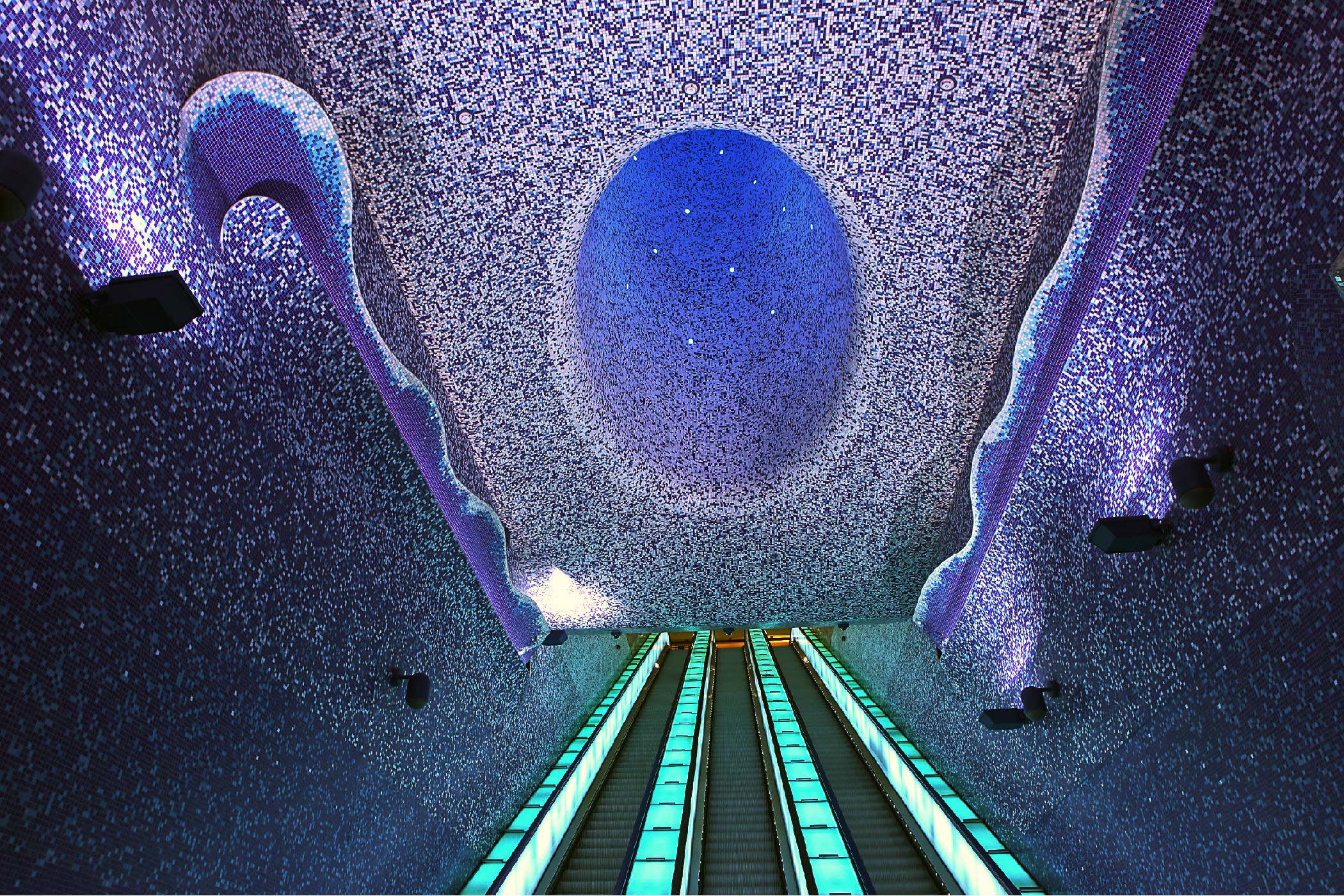

Public

spaces

Mosaics have maintained their appeal for hundreds of years. Our products make this ancient art contemporary and help to reduce the cost of construction

Versatility

of the panels

According to the characteristics of the finishing material and the application requirements, we can design and build the most suitable panel

WEIGHT-REDUCTION OF MARBLE AND MOSAICS

In the past, mosaics were made on site because the tiles were applied by hand directly on the surface to be covered. However, this traditional approach clashes with the contemporary requirement for careful time and cost planning. The pre-assembly technique has therefore gained ground, making it necessary to find “light” and efficient solutions for the transport and installation of pre-processed components. The high-tech substructure solutions offered by Starcell are an important innovation in this field.

Surface coating

The use of mosaic and stone materials is now more relevant than ever. Many rooms (in particular spas and public spaces) are entirely covered with coloured slabs and tiles. The materials have also progressed, adding new proposals: not only natural stone and glass, but also granite and reconstituted marble as well as small mosaic tiles made of synthetic materials.

Starcell has contributed to the development of mosaics and the associated construction techniques, developing lightweight panels that are a perfect substrate for the construction of the work. This means that it is possible to do the work in the workshop already on large modules and to quickly install them on site only after the composition has been completed, all this with the advantage of an extremely low overall weight thanks to the use of honeycomb cores and very thin structural skins.

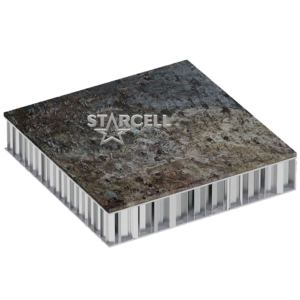

Similar advantages can also be obtained with stone which can be used just a few millimetres thick, to rationally use natural resources and achieve significant advantages in terms of savings on installation costs.

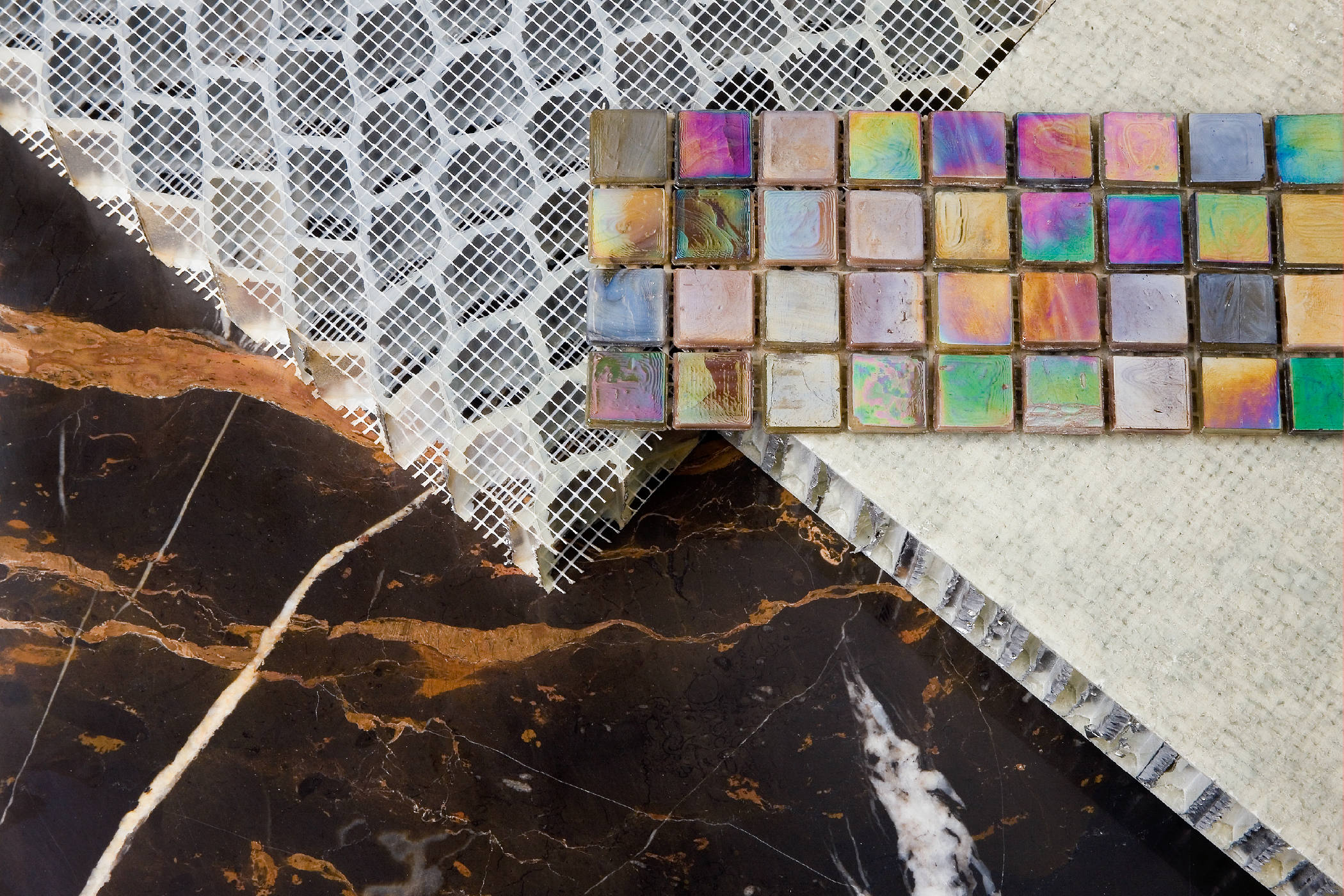

Panels with glass fibre skins

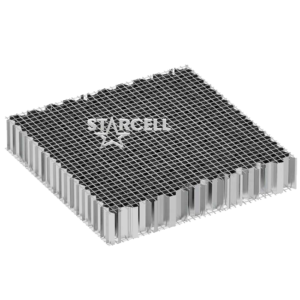

For the weight-reduction of marble and mosaics, the most performing panels are made of an aluminium honeycomb core and a wide range of glass fibre skins. Starcell can produce various thicknesses of panels and with variable cell densities, depending on load requirements.

The skins can be simple glass fibre nets in fine or wide mesh, or glass fibre mats in various densities, impregnated with epoxy resins. In addition, the panel can be reinforced on the back with an additional metal skin, which is useful if it must be fastened to a substructure (e.g. for applications on building façades).