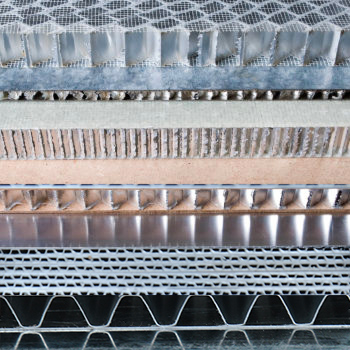

Lightweight panels

without finish

We offer a broad range of composite panels with raw skins, ready for the subsequent application of finishes

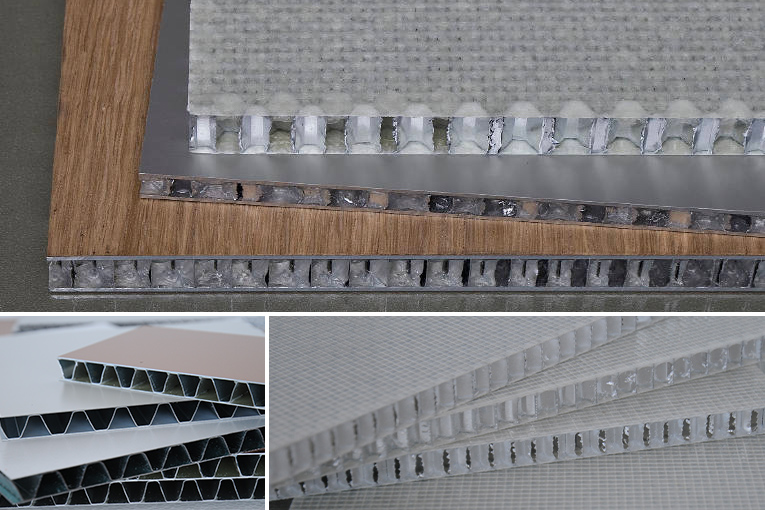

Lightweight panels

with finish

We offer panels already faced with many materials and finishes

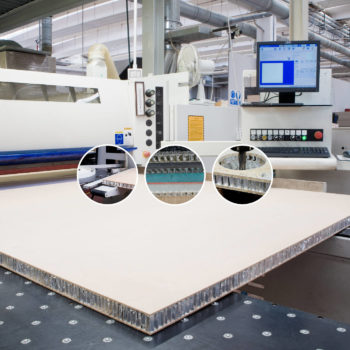

Production

lines

We operate several types of equipment to produce panels with open cells (70% of the panels produced) and closed cells (30%)

Additional

operations

We complete the panels according to customer requirements: squaring, cutting to size, edging, CNC machining and special finishing

WHAT WE DO

We manufacture aluminium honeycomb cores at our plant in Calitri (AV) and use them to make sandwich panels by applying various types of skins, with or without a cosmetic finish. We produce lightweight panels with a corrugated aluminium or galvanised steel core and ‘full core’ panels.

HOLLOW CELL PANELS

70% of Starcell’s current production consists of panels with open-cell cores. Most have aluminium honeycomb cores (manufactured in its own plant) and the rest are plastic open-cell products and panels with a corrugated aluminium or galvanised steel core.

The advantages of open-cell products are their extremely high mechanical properties (rigidity), the light weight of the finished products, their excellent fire and weather resistance and last, but not least, that their components can be almost entirely recycled.

Starcell uses three different production processes, so as to offer a broad range of skins and finishes.

SOLID CELL PANELS

In addition to its traditional production of aluminium honeycomb panels (two lines) Starcell has also developed a specific production line for sandwich and solid-core panels.

Calcium silicate, PVC, polyurethane foam, as well as multi-layer materials, MDF and, in general, any closed cell material can be used to produce an endless variety of solid core panels with appearance and performance that meet even the most diverse requirements, in terms of quality, finishes, and certification, while respecting the environment.