LITHOCELL®

We can provide the honeycomb panel with any type of natural stone, but also artificial materials such as reconstituted marble and granite, ceramics and gres (external bonding).

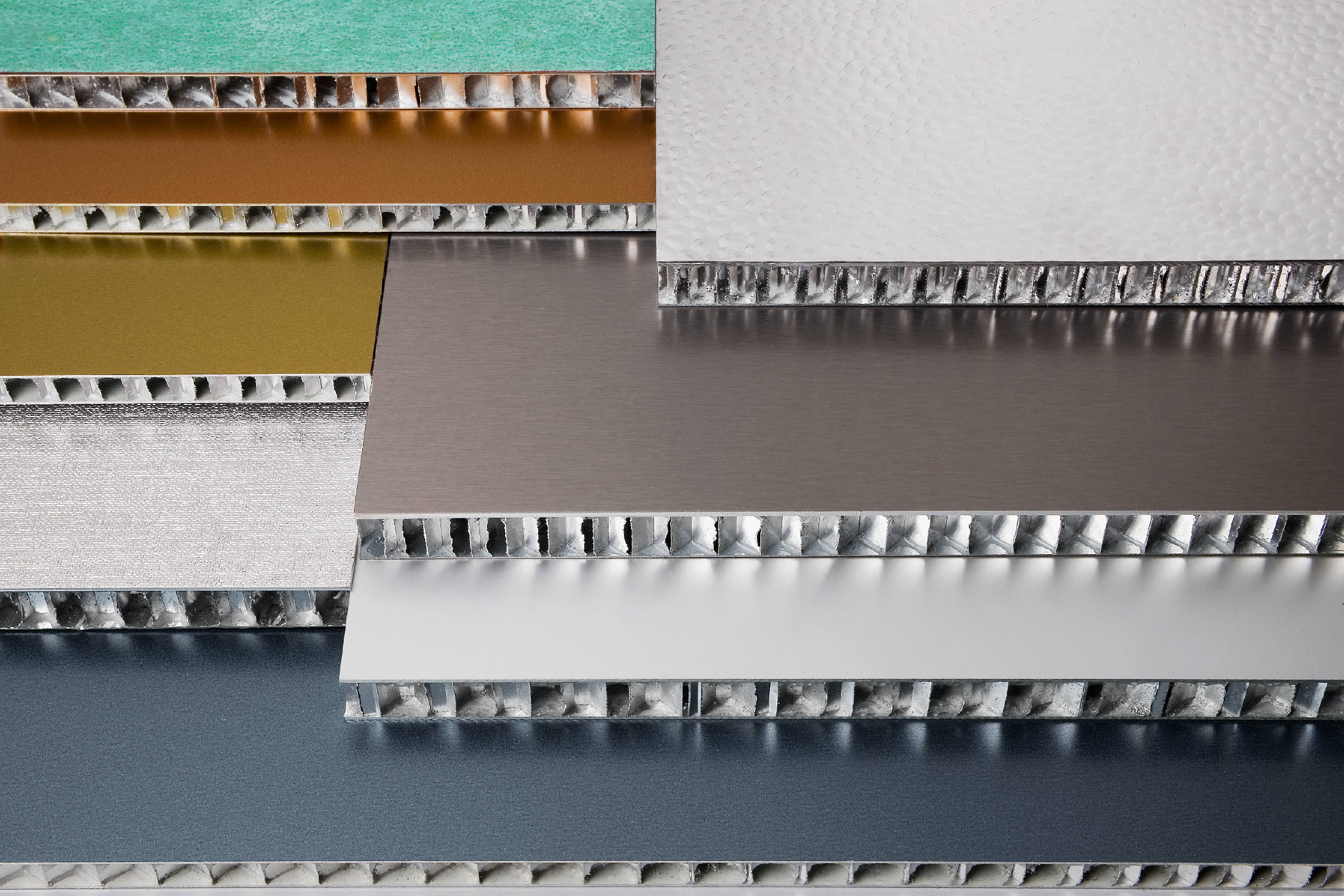

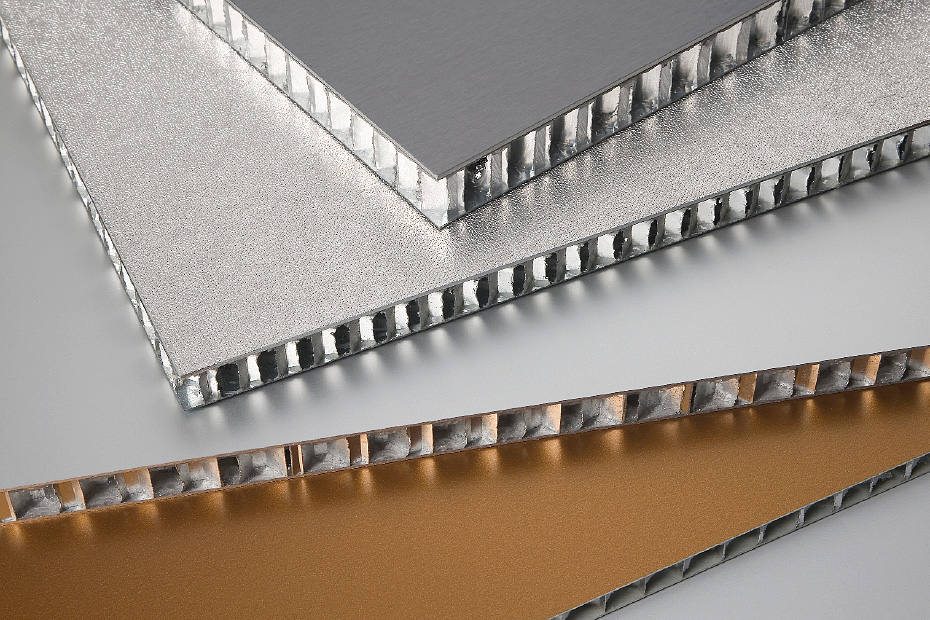

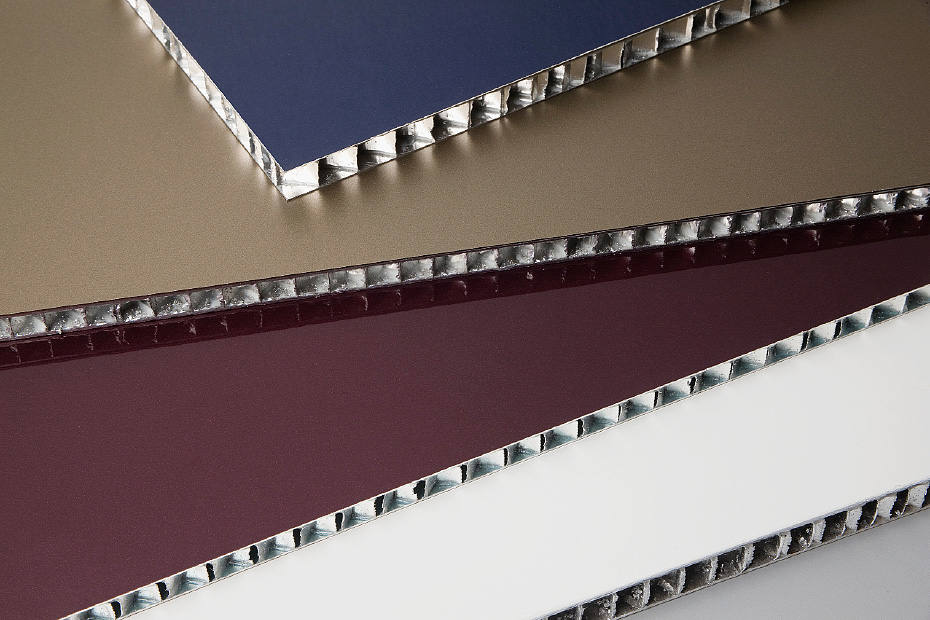

METALCELL®

We supply honeycomb panels with painted skins in a wide range of colours as well as finishes obtained by oxidation processes of metal surfaces

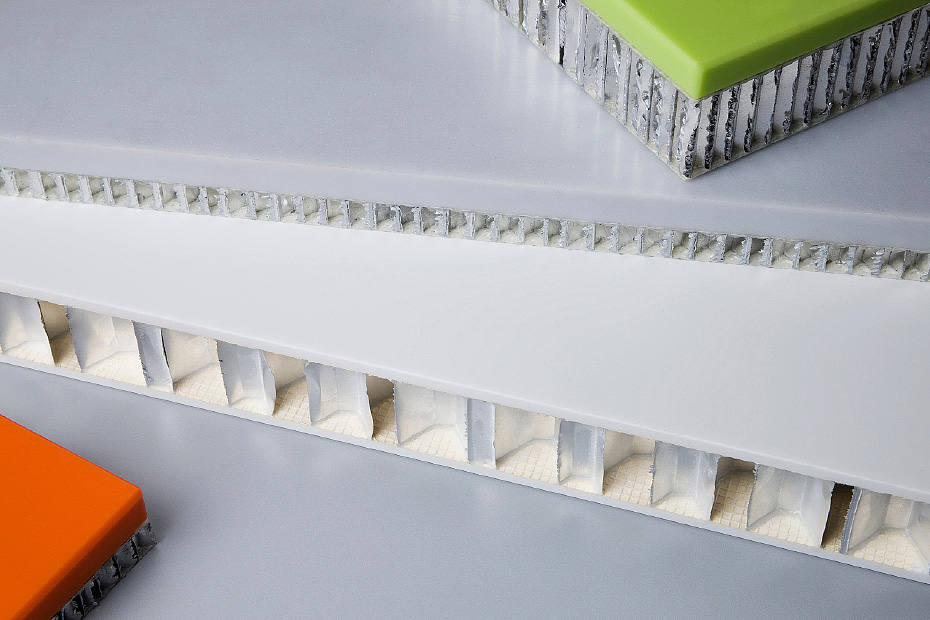

MIXCELL®

We have developed bonding solutions to finish our panels with all kinds of materials: laminates, glass, solid-surfaces and much more

HONEYCOMB PANELS WITH FINISH

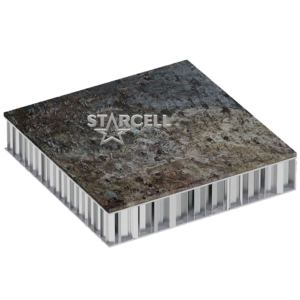

LITHOCELL® NATURAL STONE

The LITHOCELL® Natural Stone family consists of panels with a cosmetic finish layer made of natural stone. This group includes all non-polishable natural stones (e.g. slate) with a “split” finish, metamorphic calcium carbonate (marble) rocks, siliceous rocks with a crystalline structure (granite) and sedimentary rocks (e.g. travertine), regardless of the type of surface appearance (glossy, polished, bush-hammered).

Normally, a LITHOCELL® panel is obtained by gluing (action performed by marble workers, our partners, customers) a thin natural stone slab (thickness 3-5 mm) to a panel without finish such as the RAWCELL® panel. The choice of the panel used as the basis depends on the type of application. Starcell is available to help its customers evaluate the best solution case by case in relation to the desired result.

LITHOCELL® COMPOSITE STONE

The LITHOCELL® Composite Stone family includes all the panels with a finishing layer made of artificial or reconstituted stone. These are the particular materials that are produced artificially by mixing powders and fragments of natural stone (marble, granite, etc.) with binding resins that, once catalysed, replicate the consistency of stone. Since these materials are produced in the factory, they are commercially available in sheets with standard thicknesses between 6 and 25 mm.

The LITHOCELL® Composite Stone panels are designed to meet the reinforcement requirements of thinner artificial stone slabs which, in many cases, are not suitable for use without a suitable combination with an appropriate substructure.

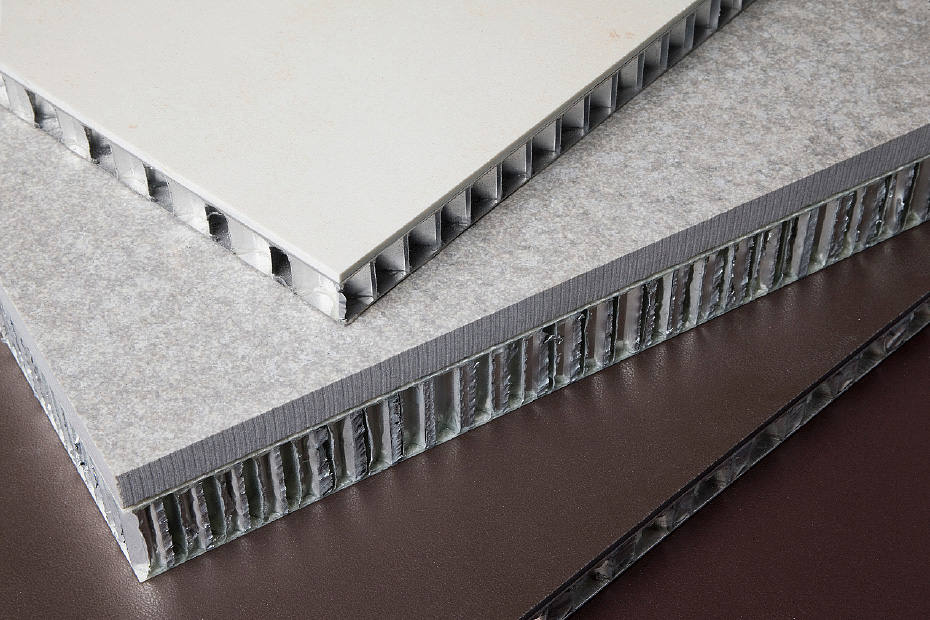

LITHOCELL® CERAMIC

The LITHOCELL® Ceramic family is obtained using RAWCELL® panels without finish by finishing them with ceramic slabs. In recent years there has been a great transformation in this field, with the introduction on the market of large-format ceramic slab products which, in many cases, have replaced traditional tiles.

LITHOCELL® Ceramic panels are an answer to the problem of using ceramic slabs in certain situations. In fact, ceramics are often produced with very low thicknesses (3 mm), which prevents direct processing of the material and makes it essential to use rear stiffeners to install them, for example, in ventilated façades or dry walls. In such situations, in fact, the loads involved (wind thrust, etc..) make use of the finishing material impossible without valid structural reinforcements.

METALCELL® ANODYZED

The METALCELL® Anodized family is the cosmetic reinterpretation of the RAWCELL® Metal FP panel without finish. This range includes all the panels that are entirely made of aluminium (both the honeycomb core and the skins) in which at least one of the two external skins is made of a sheet of aluminium that has undergone a finishing treatment that leaves the metal nature of the material unchanged: natural or coloured anodizing, satin finished, brushed, etc.

METALCELL® Anodized panels are widely used on ventilated façades and wherever a high-tech natural metal finish is required: they can be produced in various sizes and thicknesses depending on the type of application.

METALCELL® LAQUERED

The METALCELL® Laquered family includes all the panels that have at least one of the exposed sheet metal surfaces treated with a coloured decorative layer (paint). This group of products is obtained using RAWCELL® Metal panels without finish, with steel or aluminium skins.

The surface treatment may vary according to the type of requirement. Electrostatically powder-coated sheets can be used, or sprayed with water-based liquid paints and, of course, prepainted sheets can be used (coating and baking the paint).

METALCELL® RUSTY

The METALCELL® Rusty family is a cosmetic reinterpretation of the RAWCELL® Metal FPA panel without finish, in which at least one of the skins is made of Cor-Ten steel. It is a special alloy of steel with a high copper content which is very resistant to corrosion. Cor-Ten forms a thin layer of protective oxide on the surface, which therefore takes on the typical reddish-brown rusty appearance.

METALCELL® Rusty panels can be used for building façades, large doors and furniture. METALCELL® Rusty panels can be supplied in all the size variants of the RAWCELL® Metal FPA panel.

MIXCELL® LAMINATE

The MIXCELL® Laminate family consists of panels with decorative laminate skins applied directly onto an aluminium honeycomb core. The same group also includes panels that use laminate as an additional decorative layer glued to any RAWCELL® panel (without finish).

MIXCELL® Laminate panels are widely used in the interior decoration sector of civil, residential, commercial and industrial spaces and in the naval and railway sectors. While there is always a plastic laminate decoration, any other component of the panel can be determined and sized in relation to their actual use.

MIXCELL® SOLID SURFACES

The MIXCELL® Solid Surfaces family is made up of panels with a finishing layer that is several millimetres thick, mainly composed of mixtures of minerals and acrylic or polyester resins and pigments. These artificial materials are marketed under different trade names: Corian®, HI-MACS®, KRION®, STARON®, Avonite® and others. The thickness of the finishing layer ranges from 3 to 30 mm.

These materials are of high quality and very expensive, especially in the highest thicknesses. It is therefore interesting to combine thin slabs with Starcell honeycomb panels in order to improve their mechanical qualities and fire behaviour, drastically reducing the overall weight and costs.